PVC Pipe Threading Machine

JK250BP

PVC Pipe Threading Machine

The JK250BP has a threading capability of 1/2″ to 2″ PVC pipe.

JK250BP Specifications:

• 2 1/2″ ID spindle with expandable self centering chuck

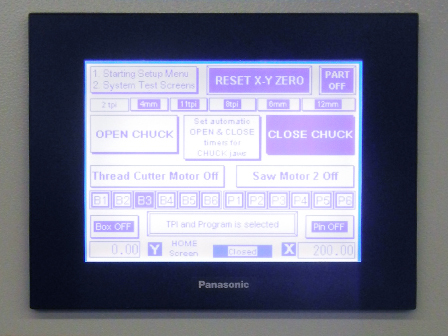

• 6″ touch screen programming for all thread dimensions

• 240 volt 3 phase

• PLC(controller) set up with program storage for 6 box & 6 pin threads

• X & Y motor table positioning performed by hybrid closed loop precision stepper actuators

Dependable and Easy to Use

This machine has proven to be extremely dependable and trouble free. This system can be compared to a scaled down version of a CNC lathe but with more simplicity and ease of operation. The long term dependability is a result of converting to an electrical system instead of air. This design simplifies the machine by considerably reducing the number of parts required to operate.

Features:

- 2 hp thread cutter motor powered by AC frequency drive

- 2 hp motor for part off & oring saw

- 1 hp gear motor for spindle powered by AC frequency drive

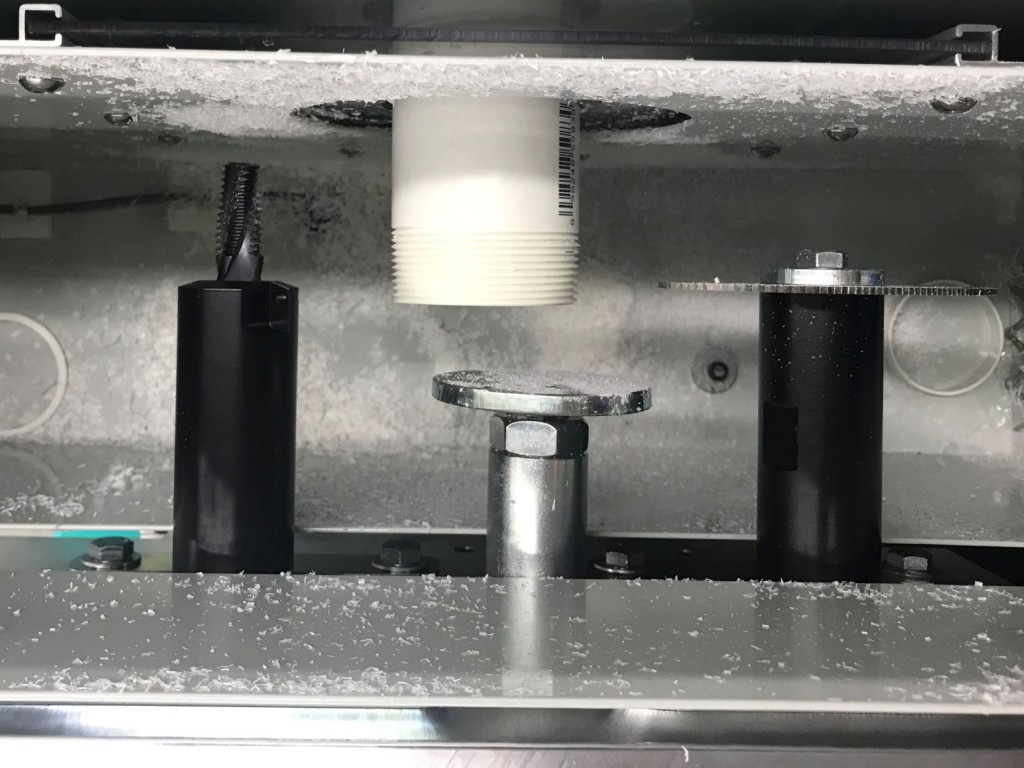

- Enclosed cutting chamber with 4″ hose adapter for vacuum (1 hp recommended)

- 15′ pipe roller support

Thread Types

The JK250 will cut thread types such as 2 TPI, 4 TPI, 8 TPI, 3 TPI, 11 1/2 NPT, 8 round taper, 6mm DIN, or 12mm DIN and more.

Thread Standards: ASTM F480, DIN4925

Additional thread types available upon request.

JK250BP Features

The JK250BP machine is equipped with one expandable self centering six jaw chuck for threading bell end pipe and flush joint (plain end) PVC pipe. Machine will thread both the male/pin end and the female/box end of the pipe.

Touch Screen Programming

Touch Screen

The touch screen programming gives you the ability to easily change thread dimensions. Each step of setting up the thread values is described on their own screen. Once you have entered the appropriate dimensions for each step, the information will be stored and will not have to be entered every time.

Machine can be setup with 6 different thread pitches. The thread ratios are easily entered through touch screen. No gears, chains or lead screws to adjust. It is all electronically linked from spindle to actuator. Some thread ratios are 2 TPI, 4 TPI, 8 TPI, 11 1/2 NPT. Changing between pipe sizes is much easier on this machine.