PVC Screen Slotting Machine

JK106STS

Single Head PVC Screen Slotting Machine

The JK106STS is a compact, space saving PVC screen slotting machine designed for pipe sizes 1/2″ through 6″ in 10 foot or 20 foot lengths by request.

Slotting Machine Details:

• 240 volt 3 phase 5 hp slotting motor.

• Safety enclosure around main slotting head assembly equipped with two doors for servicing and

windows for viewing.

• Air supply 120 psi 10cfm.

Capabilities

The standard pipe support tray is 14’ long, enabling slotting capability 1/2″ through 6″ in 10’ lengths. This machine can also be built by request with a pipe support tray for slotting 20′ lengths of pipe. The tray is designed to be stationary and anchored to the floor at both ends, which will require less floor space, approximately 4′ x 16′ for the shorter tray and approximately 4′ x 26′ for the longer tray.

The machine in mounted on four 15″ pneumatic wheels mounted on 1″ sealed taper bearings. The slotting motor assembly will then travel along the tray for each segment of slots.

Approximate Slotting Times:

6-7 minutes on 10’ of 2″ with 4 rows, 1/4″ slot spacing

8-9 minutes on 10’ of 4″ with 5 rows, 1/4″ slot spacing

Most often, a 10’ row of slots with 1/4″ spacing will take 2-3 minutes.

Times will vary depending on pipe size, saw width, amount of saws, size of saws. The machine runs the best with 20 to 25 saws.

Features

Automatic Pipe Indexing

The automatic pipe indexing for each row of slots will be performed by another high torque closed loop stepper gear motor system. The indexer is mounted on one end of the pipe support tray with floor mounts that position the pipe tray up to 32″ for easier pipe loading and unloading.

Travel System

The travel system that moves the slotting assembly will be run with a high torque closed loop stepper gear motor system. The pipe support tray will be fitted with a 3/4″ #12 gear rack on which the stepper gear motor will accurately position and move the slotting assembly for each segment of slots.

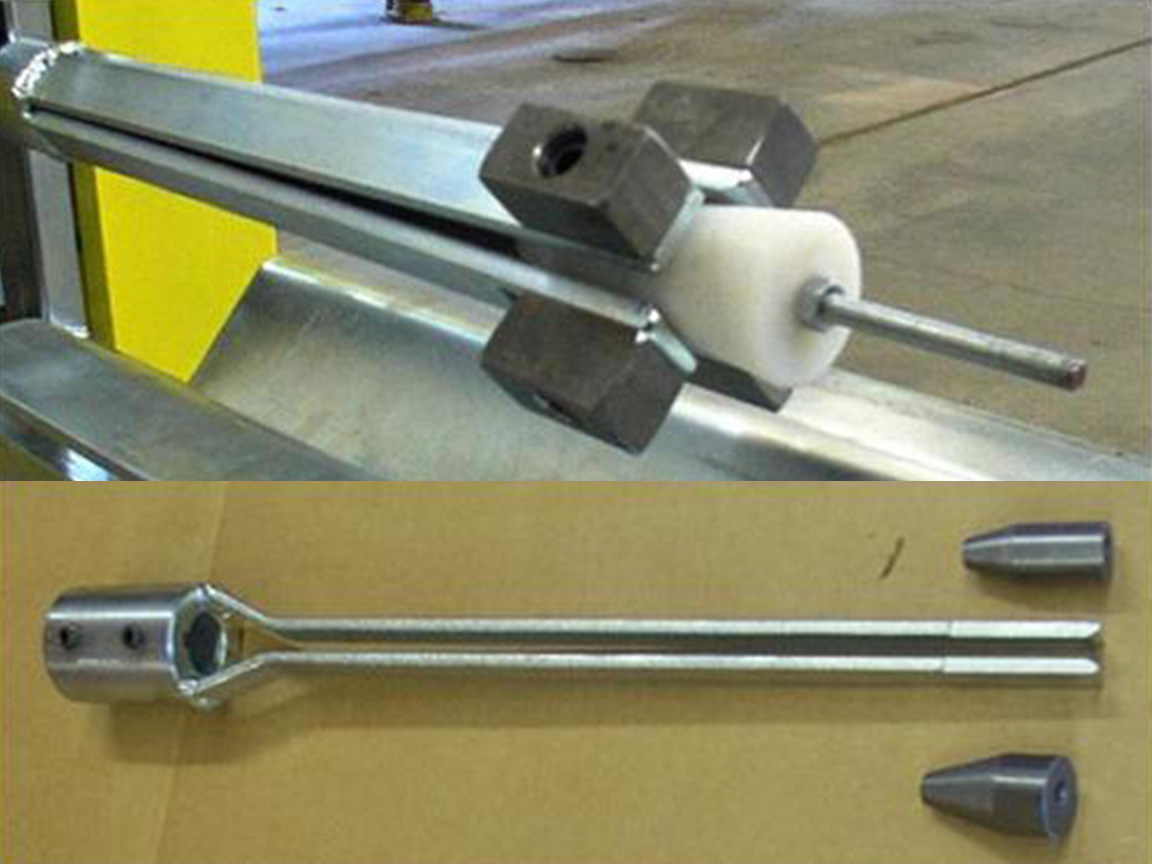

Pipe Indexing

The automatic pipe indexer will have an 1 1/4″ hollow indexer shaft to accommodate air operated inside pipe holders. Pipe to be slotted is clamped to the indexer shaft by the inside expanding pipe holders shown here.

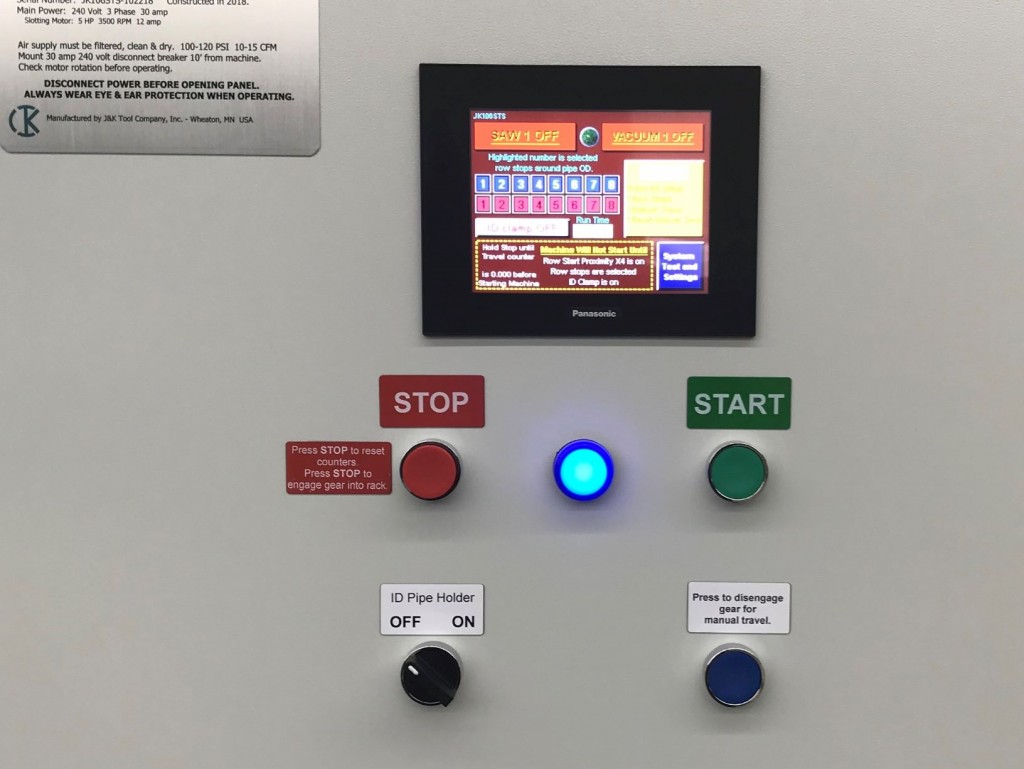

Touch Screen Programming

The pipe indexing and slotter travel distance will be monitored and set with a Panasonic GT touch screen. On the touch screen, there will be row settings for 1 up to 8 rows of slots around the pipe circumference. Also through the touch screen, you can set the travel from 0 up to 99.” The spacing between segments of slots can be set and very accurately positioned from 0 to any distance which is required within .005” – .010” tolerance.

The touch screen will be used to set the amount of rows to be slotted, display the active row, set and display the travel distance per segment of slots, display cycle time for each screen, and have manual operation buttons to test each system and speed setting for both the indexer and travel system.

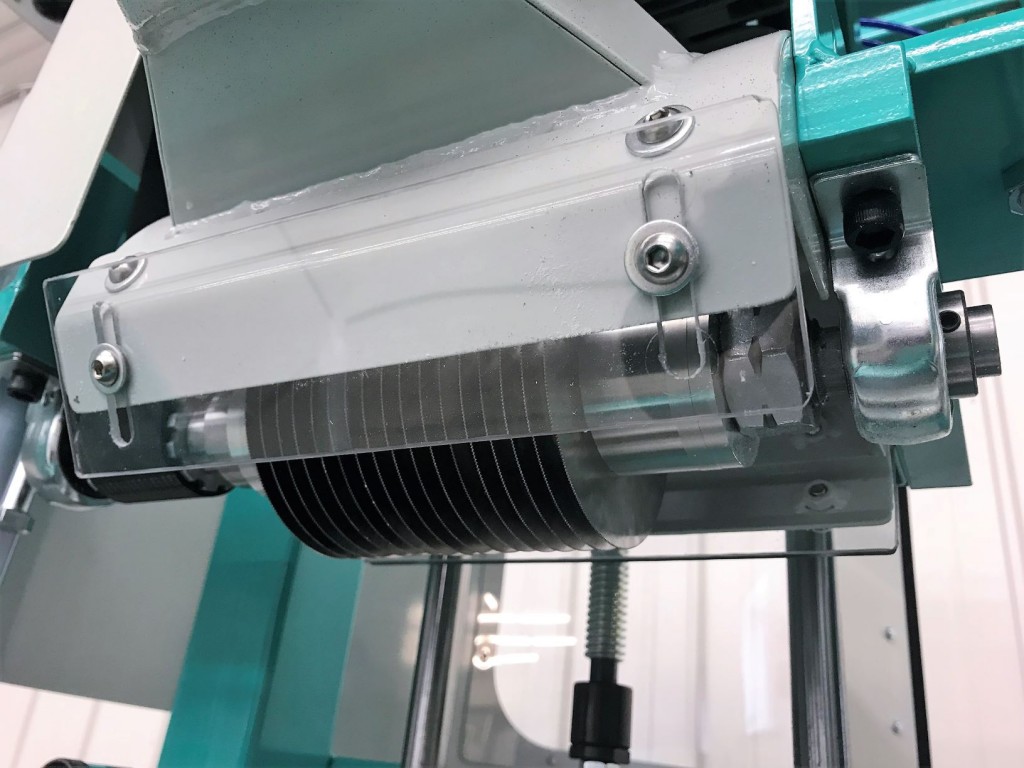

Slotting Saw Shafts & Aluminum Spacers

Aluminum spacers are also made by J&K Tool Company on a precision CNC lathe. Spacers are machined to be perfectly parallel and flat.

If the spacers are not perfectly parallel and machined within a very close tolerance, the slotter shaft will bend.

All slotting saw shafts are made out of C1144 stress proof steel on a precision CNC lathe by J&K Tool Company. Shafts are turned to the closest tolerance possible and turn true at high RPM.