Machines

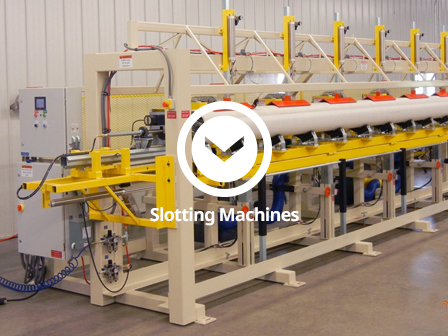

JK660-10SP

PVC Vertical Slotting Machine

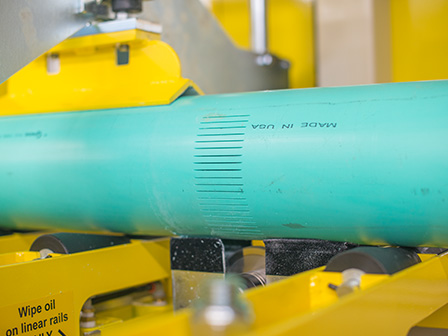

The JK660-10SP is built with 10 slotting head assemblies and will cut vertical slots in PVC pipe sizes 1 1/2” – 26” in 20’ lengths or shorter.

JK660-10SP Details:

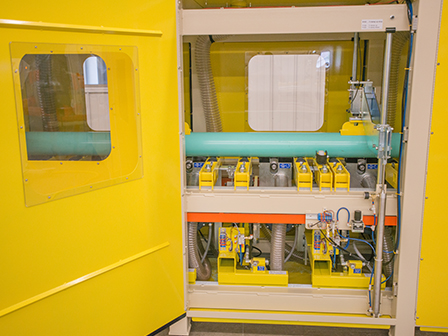

• Designed with ten 3hp 3 phase slotting motors powered by AC frequency drives.

• Machine will be completely enclosed for safety. Steel panels will have polycarbonate inspection windows and easy access doors with safety switches for the points of machine that require service and setting.

• The frame is constructed with 3” (76.2mm) and 4” (101.6mm) heavy wall square steel tubing.

Capabilities

JK660-10SP is Safe and Efficient

Located directly above the roller pipe support will be a 5 air operated automatic pipe clamp system. This system will securely clamp the full 20’ (6m) length of pipe and be self adjusting from 110mm (4”) through 660mm (26”). The Pipe support frame is equipped with 20 steel and nylon rollers to enabling easier loading of larger PVC pipe to be drilled. Pipe to be perforated will enter and exit the enclosure at one end of machine for safety and accessibility. The approximate dimensions of the machine are 27’ (8.5m) long x 46” (1.170m) wide x 81” (2.057m) high.

Automatic Pipe Indexer

The indexer has 3 primary functions

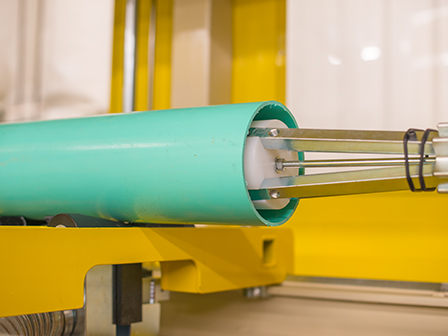

Pipe indexing unit is located inside main frame and is mounted to the lower main frame on V track wheel system. The pipe indexing unit is equipped with two high torque stepper gear motors that have two main functions. Turn the pipe to the proper preset degree and move the pipe horizontally to the next preset hole position. Pipe rotation for indexing is performed high torque stepper gear reducer. The automatic pipe indexer will have 1 1/4” (31.75mm) hollow drive shaft to accommodate air operated inside pipe holders.

Slotting Saw Shaft Assembly

The slotting shaft assembly consists of the following:

Slotting saw shafts are mounted horizontally and driven by 3hp motors with 1.5” (38mm) timing belts. Saws are mounted on shafts parallel with pipe and will move vertically up into pipe OD. Each slotting motor unit is set up with one adjustable depth setting and saw out stop setting. The vertical reciprocating movement of each slotting assembly will be air powered.

All ten slotting motor assemblies will be equipped with an adjustable independent plunge speed control and depth setting. This system is designed for PVC slotting or drilling to prevent cracking or chipping of perforated holes or slots.

The slotting motor assemblies are mounted to the lower frame on V track that runs the full length of machine. Center distance can be changed from 406mm (16”) up to 1200mm (48”) for different slot or hole patterns, inch or metric, and special applications. When an application requires a center distance more than 26” (660.4mm), slotting motor assemblies can be disabled through touch screen.

After setting all ten slotting motor assemblies, they will remain fixed on the main frame below pipe. The indexer on this machine is designed to move the pipe horizontally to the next preset slot or hole position. A roller system creates a low resistance travel of pipe to next perforation position. Horizontal left and right travel is performed by high torque closed loop stepper gear motor.

A Panasonic touch screen is used to set travel distance, off set or stagger, and the amount of perforated rows set to the degrees required. Slotting saw assemblies can be disabled and bypassed for automatic operation through the touch screen. Example: A 3 meter pipe may only need 5 slotting units to produce a screen.

Five of the saw shafts will have right hand threads and the other five will have left hand threads. In other words, 1st motor will run CW, 2nd motor CCW, third motor CW, etc. The ten Frequency Drives will change saw rotations. All ten slotting shaft assemblies will be equipped with vacuum shrouds that surround the saws and direct the cuttings into a 4” (101.6mm) collection hose. The shrouds are sized to hold up to 10” (250mm) diameter saw blades. 4” (101.6mm) hoses are connected to a 6” (152.4mm) manifold tube.