Hole Drilling Machine

JK1250-10P Perforating Machine

Perforating Machine for HDPE & PVC Pipe

The JK1250-10P Perforating Machine for HDPE & PVC Pipe is designed to drill holes in pipe sizes 4″ through 12″ in 40′ & 50′ lengths.

Features

• Equipped with ten independent 1.5hp 3 phase drill motor assemblies.

• Automatic pipe loading and pipe discharge system.

• Pipe is moved horizontal by the indexer on a system of rollers bolted to top angle track on main frame.

• 460 volt 3 phase 60 HZ; Air Supply: 15 to 20 CFM at 120 PSI

Capabilities

Features of Drilling Motor Assemblies

All ten drilling motor assemblies will be equipped with an adjustable independent plunge speed control and depth setting, designed to prevent cracking or chipping of perforated holes.

The drilling motor assemblies are mounted to the lower frame on angle track that runs the full length of machine. Center distance can be changed from 610mm (24”) up to 1524mm (60”) for different hole patterns, inch or metric, and pipe lengths 40’ and 50’.

Drilling motor assemblies can be disabled and bypassed from automatic operation through the touch screen. This is determined by the length of the pipe and amount of holes per joint.

Drilling motor assemblies can be disabled and bypassed from automatic operation through the touch screen. This is determined by the length of the pipe and amount of holes per joint.

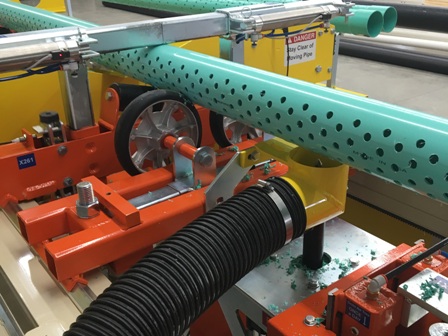

All ten drilling motor assemblies will be equipped with vacuum shrouds that surround the drills and direct the cuttings into a 4” (101.6mm) collection hose.

Automatic Pipe Indexer

Pipe Indexer

Pipe indexing unit is mounted to the lower main frame angle track on end of machine. The pipe indexing unit is equipped with two high torque stepper gear motors that have two main functions: turn the pipe to the proper preset degree and move the pipe horizontally to the next preset hole position.

Pipe rotation for indexing is performed by a high torque stepper gear reducer. The automatic pipe indexer will have 1 1/4” (31.75mm) hollow drive shaft to accommodate air operated inside pipe holder.

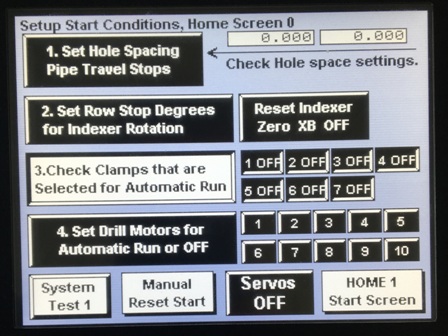

Touch Screen Programming

Panasonic PLC and touch screen are used to set travel distance, off set or stagger, and the amount of perforated rows set to the degrees required.

Drilling motor assemblies can be disabled and bypassed from automatic operation through the touch screen.

Main control panel will be connected to movable touch screen pedestals for setting and testing systems at the 10 drill station assemblies. Located on the touch screen panel will be E-Stops, program start, and program stop. Main control panels will also have E-Stops, power reset and power disconnect.

Pipe Clamps

Clamps are mounted on the pipe exit side of machine main frame. Clamps designed to retract and move down when not used to hold pipe. This feature will allow free movement of finished pipe through machine and onto pipe exit ramp.

Machine will be built with 8 self adjusting air operated automatic pipe clamps to work on 4” up to 12”.