Multiple Head PVC Screen Slotting Machine

JK1220-6HS-6VS

Multiple Head PVC Screen Slotting Machine

The JK1220 can be built with multiple slotting head assemblies for vertical and horizontal slots. The JK1220-6HS-6VS shown on this page has six 5hp motor assemblies.

JK1220-6HS-6VS Details:

• Automatic pipe feed system

• 415 volt 3 phase 50 or 60 HZ to AC frequency drives and 100 psi 15-20 cfm air supply

• Automatic pipe indexing unit is equipped with two high torque closed loop stepper gear motors

• Touch screen programming for all settings

Capabilities

JK1220-6HS-6VS is designed with six 5hp 3phase horizontal and vertical slotting motor assemblies. Motors are powered by AC frequency drives.

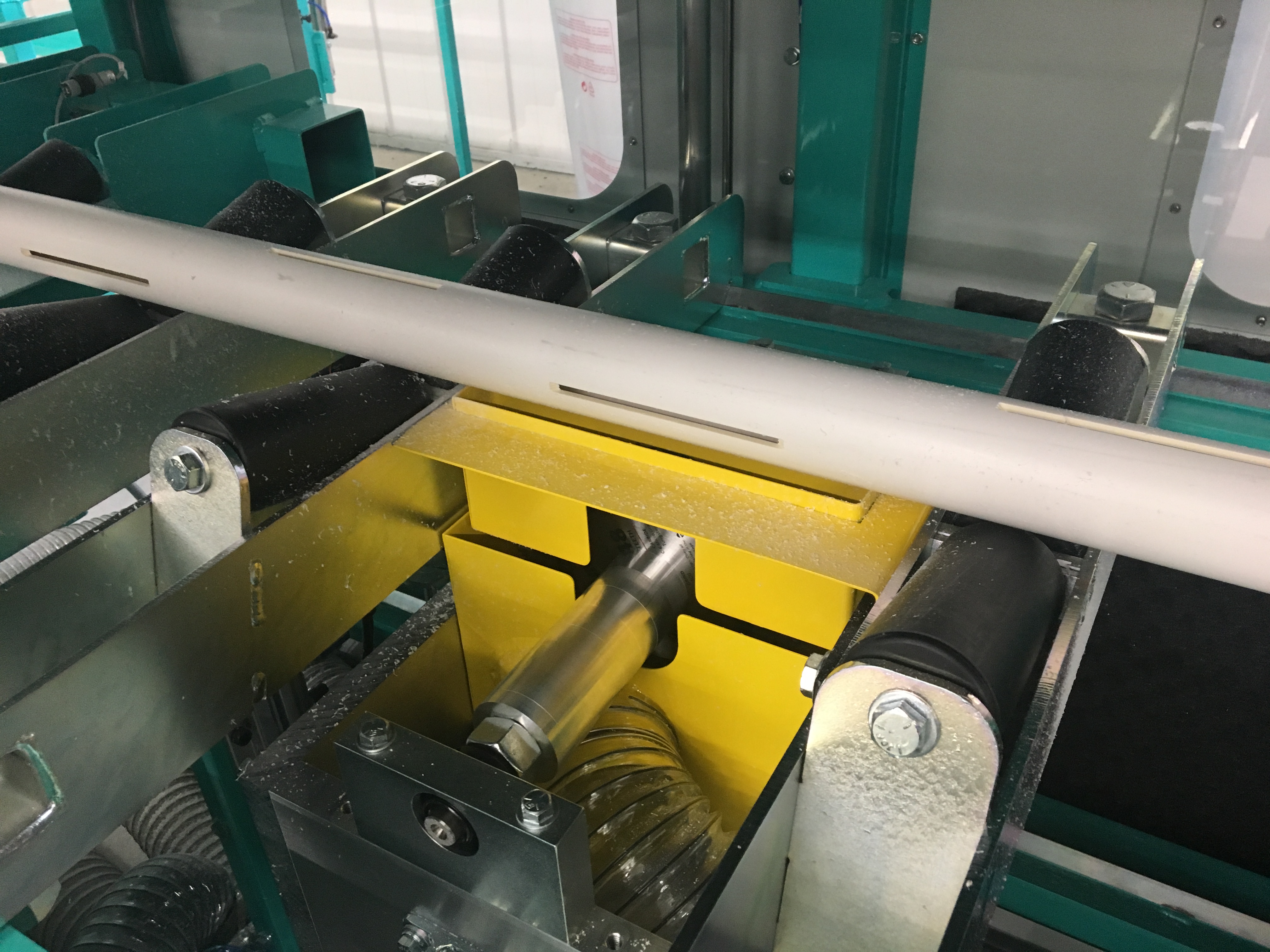

The slotting motor assemblies will pivot to change between cutting vertical or horizontal slots.

Saws are surrounded by vacuum fixtures or guarding with to 5″ hoses which are to be connected to the dust collection system.

• Slotting capability 2″-12″ (50-315mm) PVC pipe in 10′ & 20’ (3m & 6m) lengths

• Automatic pipe load and unload system

• Safety enclosure around slotting head assembly

• Machine can be programmed to slot even and odd number of rows

Cycle Time Example:

280mm (11″) OD x 16mm (.630″) wall x 6m (20′) length PVC pipe with bell

7 rows; 1mm (.039″) slot size; 10mm (.394″) spacing = 22 minutes

Automatic Pipe Indexer

The indexer has 3 primary functions

1. Clamp and hold pipe by the use of an expandable ID pipe holders located on the 1 1/4″ indexer shaft.

2. Turn pipe and accurately stop on the preset amount of rows to be cut on the pipe’s OD circumference.

3. Move pipe forward through machine to the next segment of slots to be cut.

The automatic pipe indexer is equipped with two high torque closed loop stepper gear motors. One of the stepper motor systems will

perform the operation of indexing the accurately for each row of slots and the other will move the indexer, pushing the pipe through the

machine for each segment of slots (indexer travel system)

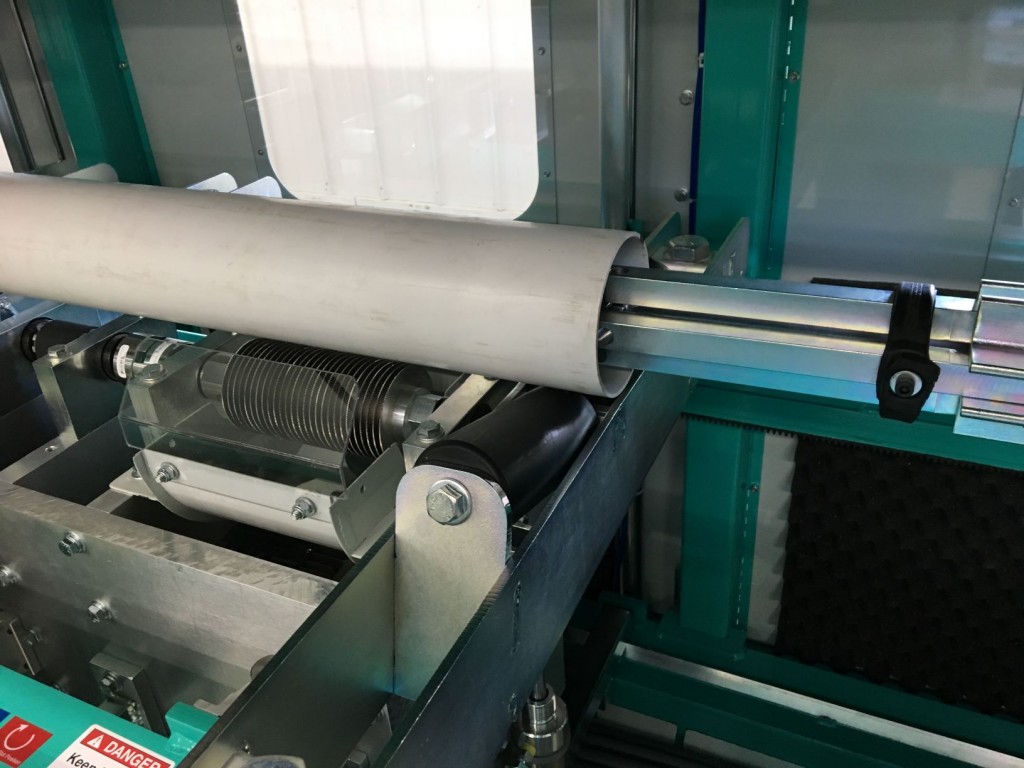

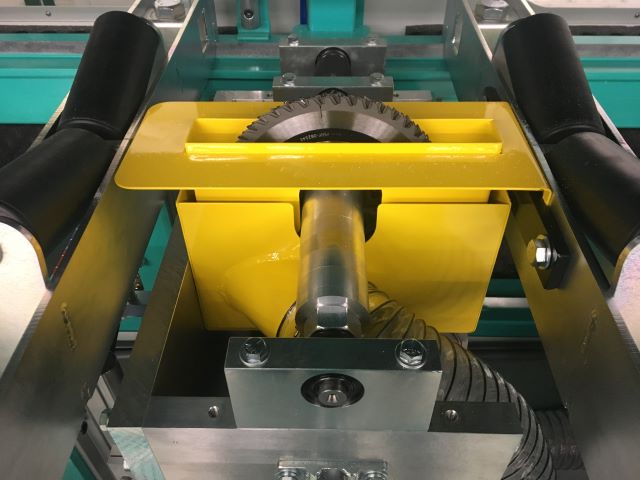

ID Pipe Holders

The pipe is held securely by the expandable ID pipe holder which is mounted to the 1 1/4″ indexer drive shaft.

ID pipe holder size #2 for pipe sizes 3″-12″

3/16” rubber oring stock is wrapped around four arms and used to collapse holding arms when air cylinder moves cone forward.

Touch Screen Programming

Touch Screen

The touch screen is located on the electrical box above the indexer. On each screen, detailed instructions are listed to assist you in the operation of the slotting machine. The pipe indexing and indexer travel distance will be monitored and set with a Panasonic GT touch screen. The touch screen will be used to set the amount of rows to be slotted, display the active row, set and display the travel distance per segment of slots, display cycle time for each screen, and have manual operation buttons to test each system and speed setting for both the indexer and travel system.

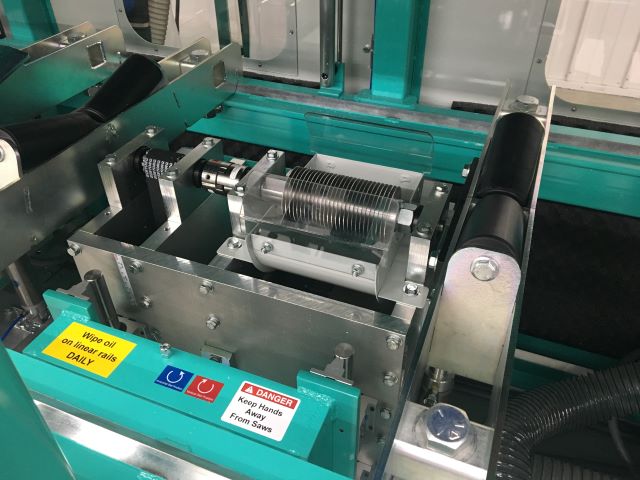

Slotting Saw Shaft Assemblies

The JK1220-6HS-6VS has two slotting head assemblies, one for vertical slots and one for horizontal slots.

Horizontal Slotting Assembly

- Shafts are 1″ with .750″ bearing ends

- Each shaft will hold maximum of 6″ of saws & spacers

Vertical Slotting Head Assembly:

All slotting saw shafts are made out of C1144 stress proof steel on a precision CNC lathe by J&K Tool Company. Shafts are turned to the closest tolerance possible and turn true at high RPM.

Aluminum spacers are also made by J&K Tool Company on a precision CNC lathe. Spacers are machined to be perfectly parallel and flat.

If the spacers are not perfectly parallel and machined within a very close tolerance, the slotter shaft will bend.

Vacuum Fixtures

The JK1220-6HS-6VS is equipped with down draft vacuum fixtures for better dust collection and will require connection to a dust collection system. J&K Tool can provide options for a collection system.

Additional Information

J&K Tool Company works directly with the customer to provide the machine which will work for your specific needs. We have built many custom designed machines, or modified our existing models. Contact us with your questions and design needs.