PVC Pipe Thread Milling Machine

JK412THRDML

Thread Milling Machine

Automated machine designed to tap pipe threads (11 1/2 TPI) into 4″-12″ PVC pipe 20’ long or shorter.

JK412THRDML Details:

• Two 2 hp motors and closed loop stepper motors

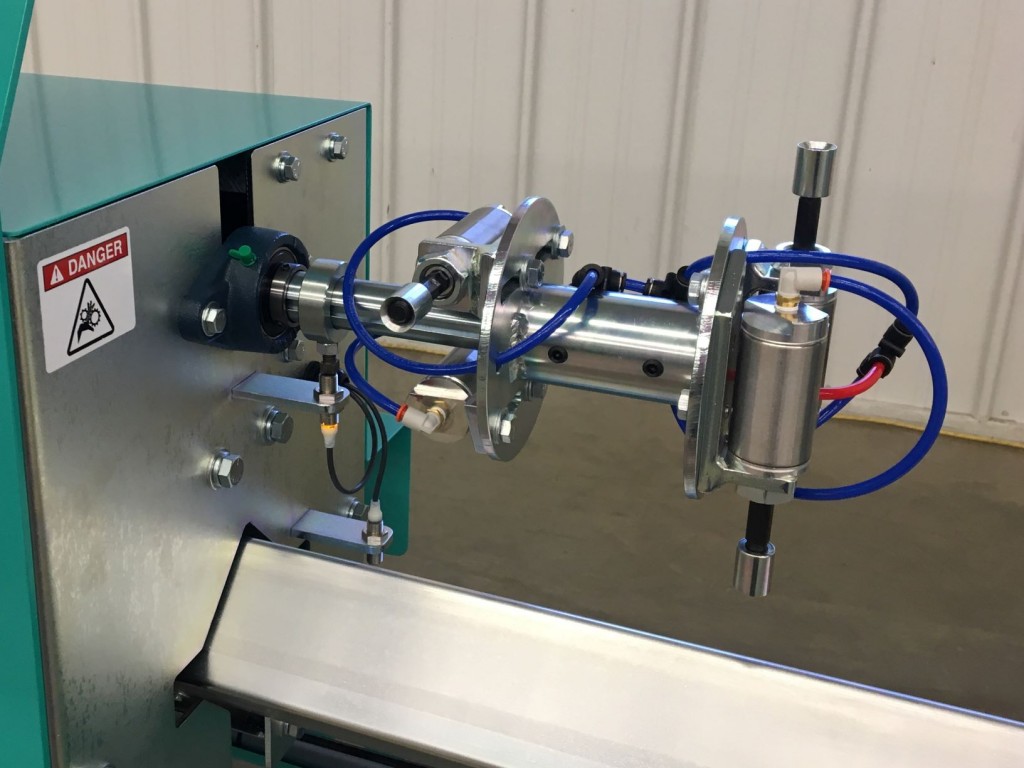

• Runs on 240 volt 3 phase (can be converted to 440/460 volt 3 phase) and 5-10 cfm 100 psi air supply

• Automatic pipe indexing unit is equipped with two high torque closed loop stepper gear motors

• Touch screen programming for all settings

Capabilities

This machine is designed to bore and thread the pipe at the same time with one special ground thread mill. The 2 HP motor will be rotated by a 1/2 HP gear motor with an encoder feed back to the PLC for electronic thread ratio gearing.

The threading process is controlled by closed loop stepper motors. Control of this system is performed by a Panasonic FP Sigma PLC programmed with Helical Interpolation software used for this type of threading.

Control panel is equipped with a GT32R touch screen which will make setup fast and easy programming for different pipe sizes.

Machine is designed to handle PVC pipe sizes from 4” up to 12” in 20’ lengths. The lower pipe support and upper pipe clamp are easily adjustable to accommodate the different pipe sizes.

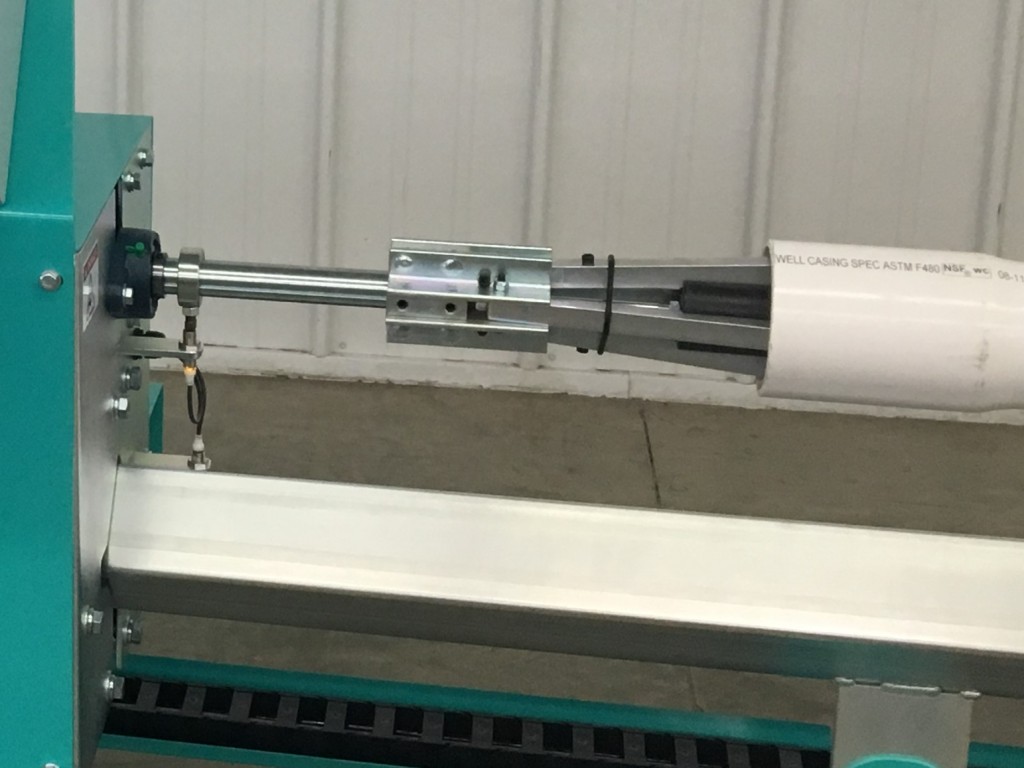

Automatic Pipe Advancing Unit

The automatic pipe advancing unit is located on the 24′ pipe travel rail. This unit is used to automatically move the pipe accurately for each tapped hole distance and will have an adjustable setting from 4” up to 16”.

The pipe advancing unit will also be equipped with an expanding inside air clamp to work on all sizes of pipes 4”-12”.

The pipe exit side of machine will have a pipe roller support for easy loading and removal of finished pipe.

ID Pipe Holders

The pipe is held securely by the expandable ID pipe holder which is mounted to the 1 1/4″ indexer drive shaft.

ID pipe holder size #2 for pipe sizes 4″-12″

3/16” rubber oring stock is wrapped around four arms and used to collapse holding arms when air cylinder moves cone forward.

ID pipe holder size #3 for holding 8″-12″ PVC pipe.

Touch Screen Programming

Touch Screen

Control panel will be equipped with a GT32R touch screen. The touch screen will make setup fast and easy programming for different pipe sizes. On each screen, detailed instructions are listed to assist you in the operation of this machine.

Thread Motor Mount

The 2 HP threading motor mount will have an adjustable 1 1/2” center. This will enable the machine to cut internal threads 1” up to 2” 11 1/2 TPI.

The boring and threading will be cut at the same time with one special ground thread mill. The 2 HP motor will be rotated by a 1/2 HP gear motor with an encoder feed back to the PLC for electronic thread ratio gearing.

Pipe Roller Supports

The pipe exit side of machine will have a pipe roller supports for easy loading and removal of finished pipe.

Vacuum Fixtures

The JK412THRML is equipped with vacuum fixtures for better PVC chip collection and will require connection to a dust collection system. J&K Tool can provide options for a collection system.

Additional Information

J&K Tool Company works directly with the customer to provide the machine which will work for your specific needs. We have built many custom designed machines, or modified our existing models. Contact us with your questions and design needs.