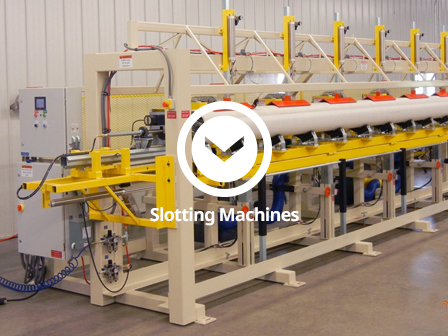

PVC Screen Slotting Machine

JK2420-4S

PVC Slotting Machine

Machine equipped with four 15 hp 240 volt 3 phase motors to run slotting shafts that hold 10” of saws and spacers.

JK2420-4S Details:

• Slotting Capability: 2” up to 24” PVC pipe in 20’ lengths

• Approximate Dimensions of Main Frame: 74” high x 46” wide x 35’ long

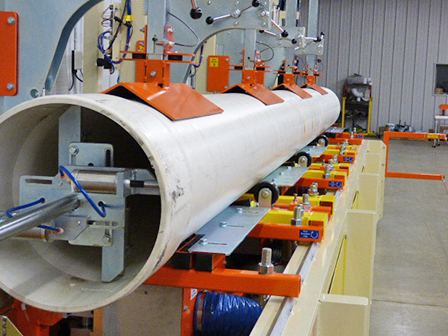

• The overhead pipe clamps are adjustable for pipe sizes 2” up to 24”.

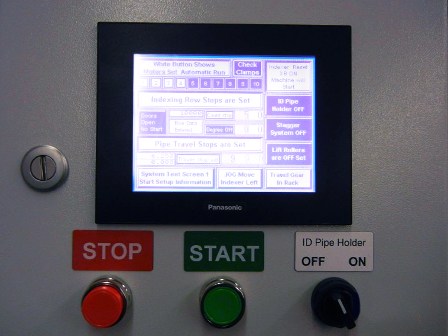

• Control panel is connected to a movable touch screen pedestal for setting and testing systems.

Capabilities

JK2420-4S is Safe and Efficient

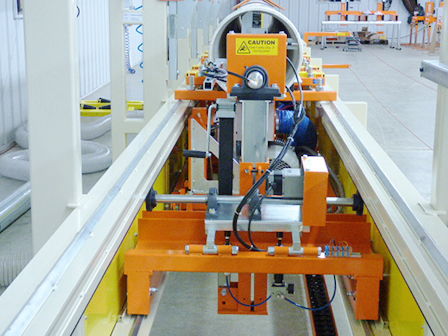

One side of the machine will be open for loading and unloading pipe to be slotted. An assembly of rollers are used for horizontal traverse of the pipe up to the ID pipe holder mounted on indexing shaft. The pipe roller supports are independent and can be easily position where needed on main frame angle track. With the fixed pipe roller system, the bottom side of most pipe sizes will be close to the same distance from saws. Change over to different pipe size requires little saw depth setting.

Automatic Pipe Indexer

Primary Functions

The automatic pipe indexing unit rides on the lower angle track located inside main frame. Power from stepper motor for travel is transferred by double geared drive shaft to dual racks on second level main frame beam. Indexer will have 1.250” hollow drive shaft to accommodate air operated inside pipe holders.

Slotting Saw Shaft Assembly

The JK2420-4S has 4 slotting shaft assemblies which increases your amount of production.

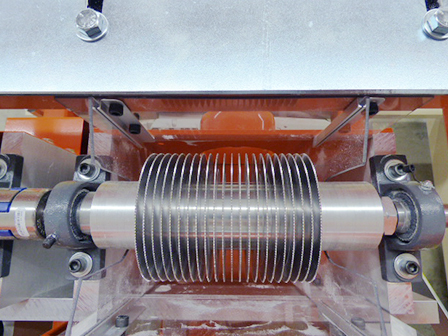

The slotting shaft assembly consists of the following parts:

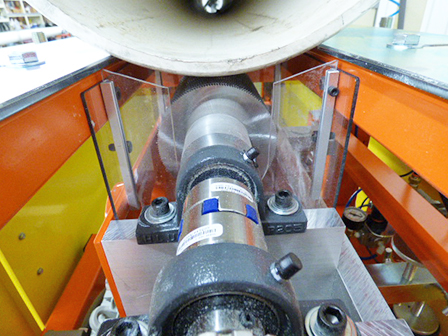

Slotting saws are positioned below pipe and can be set close to pipe OD. As a result, saws will start cut faster and drop down out of slot faster. This will decrease cycle time and heat during slotting. The movement of saws up to pipe creates a more efficient condition for dust collection. Saw arbor assembly is surrounded with vacuum shroud that will collect cuttings as saws move in and out of slots. Most cuttings and smoke will be drown down and out of slots.

The slotting motor assemblies are mounted to the lower frame angle track that runs the full length of machine. Center distance can be changed from 24” up to 48”. When an application requires a center distance more than 48”, slotting motor assemblies can be disabled through touch screen.

JK2420-4S will be designed with four 15 hp 240 volt 3 phase slotting motor assemblies. Motors are powered by AC frequency drives. Slotting saw shaft will be 1” with 1” bearing on belt side and .750” bearing on saw side. Each slotting shaft will hold a maximum 10” of saws and spacers. Slotting saw shafts are connected to 15 hp motor with drive couplings. Saws will be surrounded by vacuum fixture with 4” hoses connected to main 6” or 8” vacuum duct. 15 hp motor assembly will ride on 1.500” linear shafts and bearings. Vertical movement for slotting is done with air over fluid. Each saw assembly is equipped with regulator valve for adjusting saw cutting speed.

Touch Screen Programming

Touch Screen

The pipe indexing assembly on this machine is designed to move the pipe horizontally to the next preset slot segment and rotate the pipe for the amount of rows required. Indexing and horizontal left and right travel is performed by high torque closed loop stepper gear motors. JK2420-4S is equipped with 8’ of accurate programmable travel. Panasonic touch screen is used to set travel distance and the amount of slotted rows set to the degrees required.