PVC Pipe Threading Machine

JK500BP

PVC Pipe Threading Machine

The JK500BP has the capability to thread PVC pipe sizes: 125mm-400mm (140mm-450mm OD)

JK500BP Details:

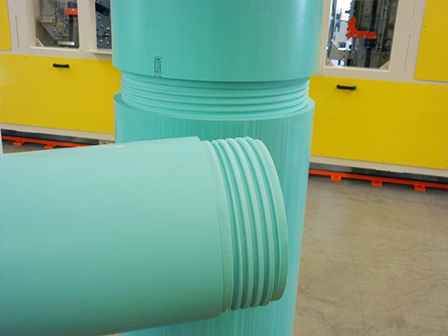

• Threading capability for plain end 140mm-500mm OD PVC pipe. JK500BP will also thread bell end PVC pipe. Bell diameter should not exceed 500mm.

• 558mm (22”) ID hollow spindle.

• Convert to 415 volt 3 phase power (includes line conditioner to correct fluctuating input voltages).

• Machine will thread both male (external) and female (internal) threads.

Capabilities

Dependable and Efficient

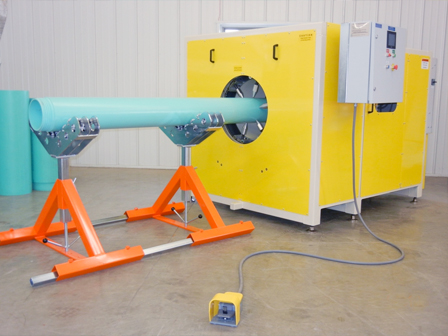

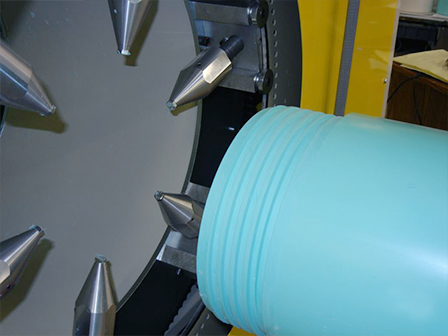

Model JK500BP is equipped with a 558mm (22”) ID hollow spindle which is rotated by a 1hp gear motor powered by an AC frequency drive. This design incorporates touch screen programming for all dimensions and movements. The automated movements are performed by hybrid stepper actuators and is controlled by a sophisticated PLC which has the capability to store 12 different thread dimension programs (6 pin and 6 box). Main machine dimensions: 66” wide x 90” long x 68” high An additional 20’ (6m) floor space required when threading 20’ (6m) pipe. This machine is equipped with two heavy duty pipe support stands equipped with multidirectional wheels and enclosed vacuum chamber surrounding pipe.

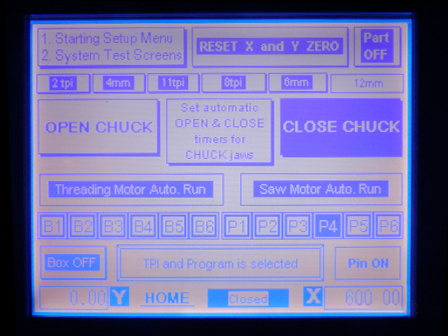

Touch Screen Programming

Touch Screen

The touch screen is located on the electrical box above the indexer. On each screen, detailed instructions are listed to assist you in the operation of the threading machine. The programmable touch screen also has a memory area for 6mm, 12mm and 2 TPI thread ratios. The thread cutting motor is a 5 hp 3500 rpm powered by an AC frequency drive. An additional 3 hp motor is used for cutting the part off to square end of pipe and cut oring groove when needed.ses and vacuum fixtures on slotting motor assemblies. This machine can also be programmed with thread ratios which meet the ASTM F480 or DIN4925 standards, such as 6mm, 12mm, 2 TPI, 4 TPI. Additional thread types can be set up. Please contact us to discuss.

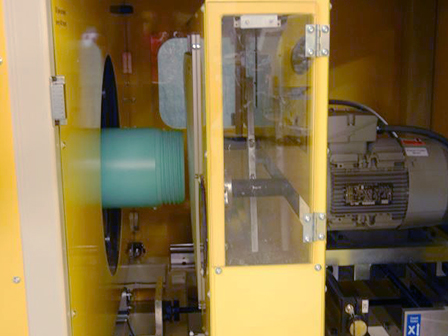

Safety Enclosure

Safety Enclosure Functions

The main frame safety enclosure around the entire threading machine-constructed of 14 gauge sheet metal; covered with steel sheet metal and polycarbonate panels for viewing; hinged doors for servicing.

• Silicon seal on top and sides of vacuum box to help contain dust and cuttings

• E-Stops (emergency stops) on each electrical panel

• Enclosed vacuum chamber surrounding pipe and cutters with a 4” (101.6mm) vacuum hose connection.

• Machine will be programmed to automatically clamp and unclamp pipe at the start and end of threading process

• Manual lubrication system for spindle.