PVC Pipe Threading Machine

JK1604BP

PVC Pipe Threading Machine

The JK1604BP is designed for threading 4″ – 16″ PVC pipe.

JK1604BP Details:

• Cuts both male(pin) and female(box) threads.

• 240 volt 3 phase (power supply can be changed for high voltage)

• Three heavy duty pipe supports equipped with multi directional wheels.

• Vacuum fixtures around cutters requires no less than 1 hp dust collection vacuum.

JK1604BP

Automated threading machine for large diameter PVC pipe up to 16″(400mm).

Equipped with expandable self centering chuck for holding flush end pipe.

Dimensions: 108″ long x 50″ wide x 60″ high; additional 20ft floor space required when threading 20ft pipe.

Capabilities

Thread Types:

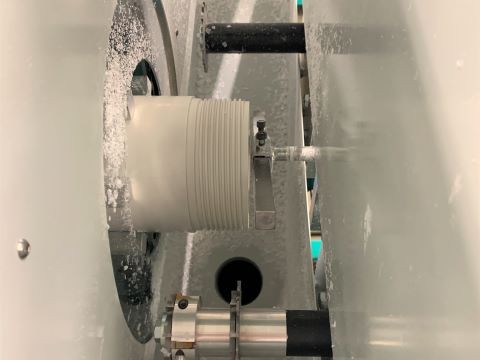

The JK1604BP will cut both male and female threads in PVC pipe following your specific requirements, such as ASTM F480 and DIN4925 standards.

Thread types include 2 TPI, 4 TPI, 8 TPI, 11 TPI, 6mm/12mm trapezoidal, 8 round taper and other types upon request. Please contact us with your requirements.

12mm Trapezoidal Thread

(shown in photo)

Dependable and Efficient

The JK1604BP is equipped with an automatic expandable self centering six jaw chuck located on each end of the spindle. The chuck system will enable the machine to thread both flush joint and bell end pipe. The chucks can be set on the touch screen to open and close manually or automatically at program start and thread completion.

The 17″ ID hollow spindle is rotated by a 1 hp gear motor powered by an AC frequency drive. This design incorporates touch screen programming for all dimensions and movements. The automated movements are performed by hybrid closed loop stepper actuators and is controlled by a sophisticated PLC (control unit) which has the capability to store 10 different thread dimensions and specifications (5 pin and 5 box). The programmable touch screen also has a memory for 6 thread ratios. The thread cutting motor is a 5 hp 3500 rpm powered by an AC frequency drive. An additional 3 hp motor is used for cutting the part off and oring groove when needed.

Touch Screen Programming

Touch Screen

The automatic pipe indexing for each row of slots will be performed by another high torque closed loop stepper gear motor system. The indexer is mounted on one end of the pipe support tray with floor mounts that position the pipe tray up to 32″ for easier pipe loading and unloading.

This machine has proven to be extremely dependable and trouble free. This system can be compared to a scaled down version of a CNC lathe but with more simplicity and ease of operation. The long term dependability is a result of converting to an electrical system instead of air. This design simplifies the machine by considerably reducing the number of parts required to operate.