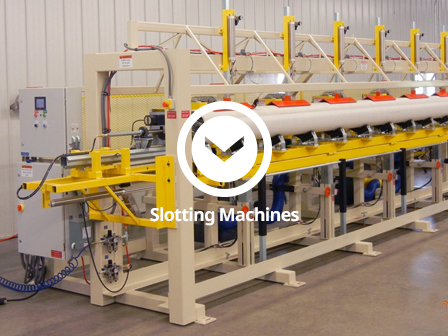

PVC Screen Slotting Machine for Large Diameter Pipe

Single or Multiple Slotting Heads

JK620

Heavy Duty Screen Slotting Machine

Because of the weight of the larger size PVC pipes, the JK620 was designed extremely heavy duty to efficiently slot quality screens 6” up to 20″.

JK620 Details:

• The JK620 has PVC pipe slotting capability from 6″-20″ in 20’ lengths & shorter.

• Setup to run on 240 or 440 volts 3 phase power.

• All control circuits transformed down to 110 Volt AC and 24 Volt DC.

Capabilities

Main Frame

The JK620 is one of our largest heavy duty machines. Main frame is constructed of 3″ x 3″ square steel tube with dimensions of 29″ high, 48″ wide, and 24’ long. The traveling slotting motor assembly is also constructed of 3″ x 3″ square steel tubing, approximate dimensions 48″ high x 36″ wide x 46’ long. Mounted on the mainframe are 20 nylon pipe rollers, enabling easier loading and unloading of large diameter PVC pipe.

Power

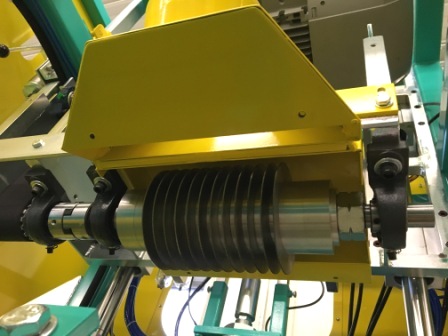

The slotting shaft is powered by one 15 hp 220/440 volt 60Hz 3 phase motor. 1 1/2″ linear shafts and bearings are used on the vertically reciprocating cutter motor and arbor assembly.

A dust collection system is required for saw cooling and plastic dust collection during the slotting operation.

Travel System

The travel system which moves the slotting assembly along the rail is run by a high torque closed loop stepper gear motor system. Also located on each side of cutter motor assembly are extra heavy built pipe clamping devices that will clamp and securely hold pipe in V rollers on main frame. The main slotting assembly is equipped with four 4″ V groove wheels that roll on angle iron rails welded to main frame.

All slotting saw shafts are made out of C1144 stress proof steel on a precision CNC lathe by J&K Tool Company. Shafts are turned to the closest tolerance possible and turn true at high RPM.

Aluminum spacers are also made by J&K Tool Company on a precision CNC lathe. Spacers are machined to be perfectly parallel and flat.

If the spacers are not perfectly parallel and machined within a very close tolerance, the slotter shaft will bend.

Automatic Pipe Indexer

JK620 Pipe Indexer

The pipe indexer is an automatic air operated 2 speed unit, designed with a 360 degree encoder for accurate pipe indexing of row stops. The automatic pipe indexer has an 1 1/4″ hollow shaft to accommodate the air operated pipe holders. Depending on pipe size and application, indexer can be set for 2, 3, 4, 5, 6, 7, 8, 9, 10, 12 rows of slots around pipe circumference.

The Indexer shaft is designed to handle air operated inside pipe holders. The ID pipe holders will clamp either plain end or bell end pipe. Indexer is also equipped with an adjustment jack used to raise and lower the unit for the different pipe sizes. This unit is also equipped with a safety switch that will not allow machine to start if the ID pipe holder is not turned on.

Machine Specifications

PVC Pipe Slotting Capability 6″ through 20″ up to 20′ lengths.

PVC Pipe Slotting Capability 6″ through 20″ up to 20’ lengths.

• 240 OR 440 Volt 3 Phase 50 or 60 HZ incoming power with control circuits transformed down to 110 Volt AC and 24 Volt DC.

• One 15 HP 220/440 Volt 60 HZ 3 Phase slotting motor.

• Air operated 2 speed automatic pipe indexing unit, designed with a 360 degree encoder.

• 1 1/4″ indexer shaft is designed to accommodate automatic air operated inside pipe holders.

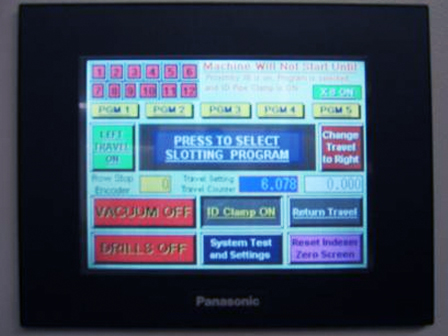

• Touch screen programming. Automatic operation controlled by Panasonic PLC.

• Control system is equipped with safety shutoff and lockout if cutter motor stops or if pipe is not clamped on indexer.

• 1-1/2″ linear shafts and bearings are used on the vertically reciprocating motor and arbor assembly.

• Machine equipped with two 3″ air cylinders used for pipe clamps located on each side of machine.

• 3″ 360H300 wide timing belt is used to drive slotter shaft, eliminating belt slippage and help to extend life of bearings and shafts.

• Slotting shaft mounts on the motor plate will accommodate 1″ pillow block bearings.

• Slotter shafts will hold a maximum of 10″ of saw blades per segment. Quantity of saws will vary because of saw spacer and saw width.

• Mounted on the mainframe are 20 nylon pipe rollers, enabling easier loading and unloading of PVC pipe.

Approximate Slotting Times:

6″ PVC, 20’ length, 5 rows, 1/4″ spacing = 15 to 18 minutes

12″ PVC, 20’ length, 10 rows, 1/4″ spacing = 30 to 35 minutes

Slotting time will vary depending on number of saws, thickness of spacer, thickness of pipe, number of rows, and size of saws.

This machine was mainly designed for the production of large diameter PVC well screens.

JK620-3SA with Automatic Pipe Feed System

JK620-3SA Heavy Duty Three Head PVC Screen Slotting Machine

- Includes three slotting head assemblies

- Slotting capacity of 4” – 20” (100mm- 500mm) pipe in 3m and 6m lengths

- Three 15hp 415 volt 3 phase slotting motor with variable frequency drive

- Safety enclosures around main slotting head assemblies

Touch Screen Programming

Touch Screen

The pipe indexing and slotter travel distance will be monitored and set with a Panasonic GT touch screen. On the touch screen, there will be row settings for 1 up to 25 rows of slots around the pipe circumference. Also through the touch screen, you can set the travel from 0 up to 999”. The spacing between segments of slots can be set and very accurately positioned from 0 to any distance which is required within .005” – .010” tolerance. The touch screen will be used to set the amount of rows to be slotted, display the active row, set and display the travel distance per segment of slots, display cycle time for each screen, and have manual operation buttons to test each system and speed setting for both the indexer and travel system.

JK630 Large Diameter Single Head PVC Slotting Machine

Slotting capability of 6″-30″ (168mm-762mm) pipe in 20′ (6m) lengths or less. (modified JK620)

Additional Information

J&K Tool Company works directly with the customer to provide the machine which will work for your specific needs. We have built many custom designed machines, or modified our existing models. Contact us with your questions and design needs.